Comprehensive Water Treatment Chemicals

Enhance your water treatment chemical process with a diverse range of advanced solutions for maximizing sustainability and efficiency.

Explore Our Water Treatment Services

Ultimately, safety and sustainability are our top priorities. That’s why we provide contact-free chemical deliveries, advanced storage options with leak detection, and round-the-clock emergency support. This allows you to reduce wasted resources and optimize your systems with unmatched efficiency. With certifications like NSF, Kosher, Halal, and compliance with FSMA and GRAS, you can trust our products meet the highest safety and quality standards, giving you the support you need to achieve your goals.

Top Chemical Water Treatments

We proudly support a wide range of industries with custom water treatment services, each designed to tackle specific water treatment challenges. Our solutions ensure efficiency, compliance, and sustainability, from boilers to potable water and every demand in between.

Cooling Towers

Combat scale, corrosion, and microbial growth and extend your water treatment equipment’s lifespan with Apex.

When you choose Apex, you choose innovative technologies and an unwavering commitment to regulatory compliance and safety. Our cooling tower solutions are designed to preserve the integrity of your equipment and protect your operation from incurring the costs of damage.

Profect™ Mild Steel Corrosion Inhibition: Provides superior system protection during upsets, offering better asset protection with a lower environmental footprint. Profect™ uses low to zero phosphorus options, resulting in lower oxidant demand and premium results at traditional program costs.

YellowGuard™ Yellow Metal Corrosion Inhibition: Excels in resisting oxidant spikes and providing tenacious surface protection. YellowGuard™ is more environmentally friendly and ensures robust protection for yellow metals.

Green Inhibitors and Safe Acid Options: Our green inhibitors and safe acid options are designed to be environmentally friendly while maintaining high performance.

24/7 Feedback Control Capabilities: Ensure optimal system performance with continuous monitoring and automated adjustments.

Microbial Control: Manages microbial growth to maintain water quality and prevent system fouling.

Foam Control: Minimizes foam formation to improve system efficiency.

pH Control: Maintains optimal pH levels to enhance system performance and stability.

Monitors: Advanced monitoring solutions for real-time feedback and control.

Inspections: Regular inspections to assess and maintain cooling tower efficiency.

Efficiency Monitoring: Continuous monitoring of cooling tower and heat exchanger efficiency.

Microbial Count Monitoring: Ensures microbial levels are controlled to prevent biofouling.

Fluctuations and Make-Up Quality: Manages fluctuations in water quality to maintain optimal system performance.

Boilers

Ensure maximum efficiency and optimal performance with solutions tailored to the unique demands of your boiler systems.

Providing greater efficiency and reliability is what we do. Apex specializes in providing water treatment services that tackle common boiler system threats, such as corrosion, scale, and contamination, all while ensuring sustainability and compliance.

FilmPro™ Filming Programs: Highly safe, environmentally friendly, and suitable for high-purity applications. FilmPro™ offers supercritical pressure acceptance, FAC protection, and excellent use-case economics, ensuring minimal impact on critical components.

iBoiler™ Pretreatment + Chemical Program: This program reduces water, energy, chemical usage, and CO2 emissions. iBoiler™ delivers better results with no capital costs and maintenance handled by Apex, all for one fixed monthly cost.

Advanced Organic Passivating Agents: Provides superior protection against corrosion and scale, enhancing the longevity and efficiency of your boiler systems.

Phosphates: Prevents scale formation and controls alkalinity.

Amines: Ensures proper pH control and protects condensate systems.

FilmPro™ for High-Pressure Boilers: Ideal for high-pressure applications, providing robust protection and efficiency.

Oxygen Scavengers: Ensures the removal of dissolved oxygen, preventing corrosion.

Reporting Structure: Detailed and digitized service reports for comprehensive system analysis.

Inspections During Outages: Thorough inspections during maintenance periods to assess and optimize system performance.

Continuous Monitoring: Ongoing monitoring of results and contaminants to ensure optimal performance.

Consulting on Contaminants: Expert consultation to identify and address contaminants, maintaining compliance with EPRI standards.

High-Purity Analysis: Advanced analysis of contaminants in condensate, steam, and feed water to ensure system integrity.

Expert Maintenance: Apex’s experts ensure the right chemical is used in the right place, in the right amount, providing a full-service approach rather than just supplying products.

Source Water

Maximize efficient water usage with pretreatment chemicals for water derived from natural sources.

We ensure your systems run efficiently before source water even reaches the reverse osmosis system. Our pretreatment chemicals eliminate suspended solids in inlet water, rivers, and other surfaces, protecting the integrity of your process equipment and optimizing your results.

Research and Innovation: Our team is continuously exploring new raw materials and chemical combinations to bring innovative solutions and added value to our customers.

Comprehensive Approach: We evaluate performance in controlled environments to develop effective chemical offerings for our clients.

Coagulants: Available in inorganic, organic, and blended forms to effectively remove suspended solids and reduce turbidity.

Flocculants: Enhance particle aggregation and sedimentation for improved water clarity.

Bentonite Clay Slurry: Utilized for its high adsorption capacity to remove impurities and enhance clarification.

Anti-Foams: Control and reduce foam formation to maintain system efficiency.

Odor Control: Manage and mitigate odors in water treatment processes.

Sludge Dewatering Aides: Improve sludge dewatering efficiency, reducing disposal costs and volume.

Source Water Analysis: Comprehensive analysis of source water upstream of clarifiers to identify contaminants and treatment needs.

Clarifier Performance Evaluation: Assess and validate the performance of clarifiers by measuring turbidity and other key parameters.

Efficiency Rating: Trend efficiency ratings by comparing inlet and outlet turbidity to ensure optimal removal efficiency.

Contaminant Removal: Track removal efficiency of metals, TOC, BOD, phosphates, and other contaminants to maintain water quality standards.

Customized Reporting: Provide detailed service reports branded for Apex, offering insights and recommendations for continuous improvement.

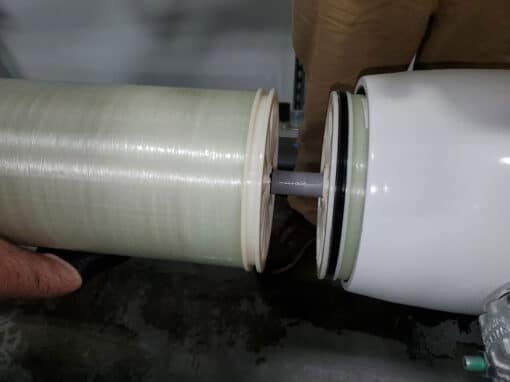

Membranes

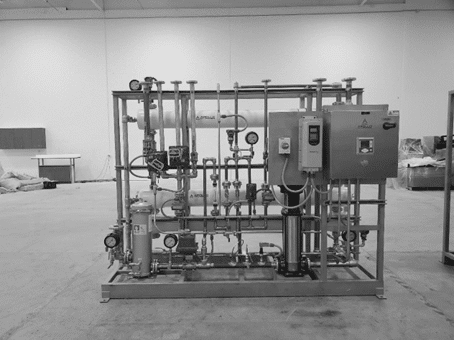

Maintain optimal membrane performance and extend equipment lifespan with advanced methodologies for reverse osmosis, RO, systems.

We offer cutting-edge water treatment chemicals to prevent scaling, fouling, and oxidant attack, along with robust monitoring and cleaning services. Together, these features combine to create a high-performance solution that reduces costs and maximizes results.

CLO2: We leverage chlorine dioxide for effective oxidant control and disinfection.

Advanced Oxidation: Our services include cutting-edge oxidation technologies for superior contaminant removal.

Chemical Feed and Storage: Access precision feed and safe storage solutions to ensure accurate dosing and safety.

WaterSim™: We utilize advanced simulation tools to optimize membrane performance and treatment processes.

NSF Certified: Apex is proudly certified to NSF/ANSI 60

Oxygen Scavengers: Destroy oxidant residual to prevent oxidative damage to membranes.

Microbiocides: Control microbial growth to maintain water quality and membrane integrity.

CIP Chemistries: Suite of clean-in-place (CIP) chemicals for effective membrane cleaning and maintenance.

Potable (NSF 60) Options: Certified products for potable water applications, ensuring safety and compliance.

Traced Options: Chemistries with tracing capabilities for accurate feed and monitoring.

Cleaning Service: Regular and thorough cleaning services to maintain membrane efficiency.

Autopsy: Destructive and non-destructive testing of membranes to diagnose issues and optimize performance.

Monitoring: Continuous monitoring of membrane performance to identify and address issues promptly.

Membrane Replacement: Professional membrane replacement services to ensure seamless operation.

Commissioning/Decommissioning: Expert support for the commissioning and decommissioning of RO systems.

Effluent Analysis: Detailed analysis of effluent to monitor and improve water quality.

Consulting: Expert consulting services to optimize your RO system performance.

Service Reports: Comprehensive service reports to provide insights and recommendations for continuous improvement.

Water Sim: Advanced simulation tools to predict and optimize membrane performance.

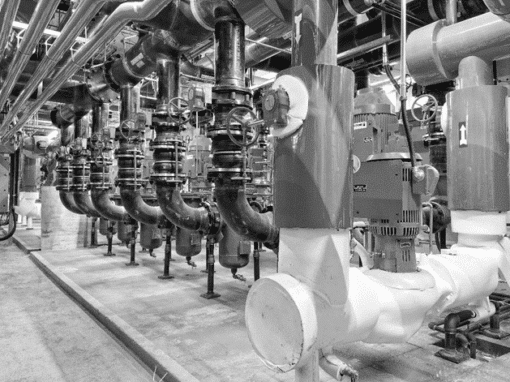

Closed Loops

Reduce long-term maintenance costs and ensure unparalleled safety with tailored solutions for closed-loop systems.

Without reliable closed-loop chemical treatments, you could risk scale, corrosion, and microbial growth on your equipment, reducing its lifespan and increasing maintenance costs. Apex is here to help combat these risks while improving safety in your workplace by using best-in-class water treatment services.

Comprehensive Support: We ensure precise chemical dosing and safe storage solutions to maintain optimal system performance.

InsituChem ClO2: Our services include chlorine dioxide for effective biological control within closed-loop systems.

FilmPro™ Filming Programs: We provide high-purity, low-conductance solutions suitable for mixed metallurgy applications, providing superior protection and efficiency.

On-Line Measurement & Leak Detection: Access advanced technologies for real-time monitoring and leak detection, ensuring system integrity and safety.

Microbiocides: Control microbial growth to maintain water quality and system efficiency.

High Purity/Low Conductance Chemicals: Ensure high performance in mixed metallurgy systems, reducing the risk of contamination and inefficiencies.

Heat Exchanger Efficiency Monitoring: Regular assessments to maintain and improve heat exchanger efficiency.

Borescope Inspections During Outages: Detailed inspections during maintenance periods to identify and address potential issues.

Service Reports: Comprehensive, digitized reports providing insights into system performance and recommendations for improvement.

Corrosion Coupons: Use of corrosion coupons to monitor and assess corrosion rates, ensuring optimal protection and maintenance strategies.

Glycol

Diversify water treatment chemicals with specialized solutions that enhance glycol performance in your systems.

From propylene and ethylene glycol, inhibited and uninhibited, our solutions are tailored to ensure optimal performance and protection. Our expertise extends to adding inhibition to existing glycol loops and recommending the best glycol fit for your specific goals. With continuous monitoring and detailed reporting, we ensure your glycol systems operate efficiently and reliably.

Expert Consulting: Access our extensive knowledge and experience in glycol applications, ensuring the best solutions for your needs.

Product Variety: We provide an extensive range of glycol products, including inhibited, uninhibited, traced, and non-traced options.

Custom Solutions: Our services include tailored glycol solutions to fit specific system requirements and operational goals.

Propylene Glycol (PG): Suitable for various industrial applications, offering excellent thermal stability and low toxicity.

Ethylene Glycol (EG): Widely used for its superior heat transfer properties and cost-effectiveness.

Inhibited Glycol: Formulated to prevent corrosion and extend the lifespan of your equipment.

Uninhibited Glycol: Provides flexibility for custom inhibitor additions based on specific needs.

Traced and Non-Traced Glycol: Ensures accurate feed and monitoring, enhancing system performance.

Active Concentration Determination: Utilizing refractometers and water analysis to ensure optimal glycol concentration levels.

Corrosion Monitoring: Use of corrosion coupons to assess and mitigate corrosion rates.

Chemical Consulting: Expert advice on the best glycol solutions and practices for your systems.

Detailed Reports: Comprehensive reporting on system performance, glycol concentration, and corrosion rates.

Chemical Deliveries: Reliable supply of glycol products in various quantities, from pails to tankers.

Chemical Feed Systems: Advanced feed systems for precise glycol dosing and control.

Wastewater Treatment

Ensure maximum safety in wastewater treatments with comprehensive solutions for every aspect of your operation.

We’re on a mission to address a wide range of contamination and treatment challenges, especially those related to wastewater treatment. Apex offers cutting-edge chemical solutions for dewatering, scrubbers, and beyond. These equipment and chemical processes ensure that your systems operate efficiently and comply with all regulatory standards, allowing you to confidently serve your customers.

WaterSim ™ : We use advanced simulation tools to optimize water treatment processes and achieve desired outcomes.

Equipment Expertise: Our team delivers extensive experience with clarifiers, strainers, filtration, and solids handling equipment, providing tailored support for your needs.

Advanced Oxidation: Our water chemical services use advanced oxidation technologies for superior contaminant removal and water quality improvement.

Coagulants: Inorganic and organic coagulants to effectively remove suspended solids and reduce turbidity.

Flocculants: Enhance particle aggregation and sedimentation for improved water clarity and solids removal.

Anti-Foams: Control and reduce foam formation to maintain system efficiency.

Odor Control: Manage and mitigate odors in wastewater treatment processes.

Sludge Dewatering Aides: Improve sludge dewatering efficiency, reducing disposal costs and volume.

Slurries: Specialized chemical slurries for various water treatment applications.

Performance Monitoring: Continuous monitoring of contaminant removal and solids handling performance to ensure optimal system operation.

Consulting Services: Expert consultation on chemical feed rates, chemical choice, and proper application of treatment chemicals.

Detailed Reporting: Comprehensive reports on system performance, removal efficiency, and cost analysis, with recommendations for improvements.

Quantifying Costs: Analysis of treatment costs and recommendations for cost-effective improvements.

Chemical Delivery and Storage: Reliable supply and safe storage of treatment chemicals, ensuring continuous operation.

Bioaugmentation

Enhance the biological treatment processes in your wastewater systems with our advanced water treatment chemical methods.

We specialize in introducing specific microorganisms that safely and effectively improve the breakdown of organic contaminants, enhancing overall system performance and efficiency. With Apex’s advanced technologies and expert services, you can optimize your wastewater treatment processes, reduce operational costs, and achieve sustainable water management.

WaterSim ™: We utilize advanced simulation tools to optimize bioaugmentation processes and create reliable outcomes.

Water Reuse: Our solutions strive to enhance water reuse, contributing to sustainable water management practices.

Analytical Services: We offer comprehensive analysis to monitor the effectiveness of bioaugmentation and ensure optimal performance for your water treatment and process.

Advanced Oxidation: Our water chemical services use cutting-edge oxidation technologies to support and enhance biological treatment processes.

Customized Microbial Blends: Tailored microbial solutions to target specific contaminants and improve degradation rates.

Monitoring: Continuous monitoring of bioaugmentation performance to ensure the effective breakdown of organic contaminants.

Consulting: Expert advice on the implementation and optimization of bioaugmentation processes.

Reporting: Detailed reports on system performance, treatment efficiency, and recommendations for improvement.

Cost Analysis: Quantification of chemical costs and identification of cost-effective solutions and improvements.

Recommendation for Improvements: Strategic insights and recommendations to enhance the efficiency and effectiveness of bioaugmentation processes.

Dust Control

Eliminate harmful dust particles with advanced dust control chemicals tailored to your operation’s needs.

Fugitive dust poses significant hazards to your water treatment and process and increases operating costs due to product loss. That’s why we offer comprehensive dust control chemicals tailored to your specific needs. We ensure the right chemicals are used at the right time and in the right amounts, minimizing dust effectively and efficiently. Whether you need manual or automated systems, we provide solutions that enhance safety and operational efficiency.

Expert Insight: Extensive knowledge in dust control chemicals and applications, ensuring optimal results for your systems.

Automation Capabilities: Full automation options for feed systems, utilizing both feed-forward and feedback criteria to optimize dust control.

Customized Solutions: Tailored recommendations for chemical use, feed rates, and application timing to suit your specific operational needs.

Foam-Based Products: Effective at minimizing dust with minimal moisture addition.

Residual Products: Long-lasting solutions that provide sustained dust control over time.

Feed Rate Determination and Monitoring: Expert assessment and continuous monitoring of chemical feed rates to ensure optimal dust control.

Chemical Use and Effectiveness Monitoring: Ongoing evaluation of chemical application to ensure desired dust control outcomes.

Automation Recommendations: Provision of automation options to minimize manual intervention and enhance efficiency.

Moisture Penalty Calculation: Analysis and management of moisture addition to minimize impact on operations.

Detailed Reporting: Comprehensive reports on dust control performance, chemical use, and recommendations for improvement.

Chemical Delivery and Storage: Reliable delivery and safe storage solutions for all dust control chemicals.

Potable Water

Maximize your treatment process for potable water systems with expertly tailored chemicals that ensure safety and sustainability.

With the growing concerns over waterborne pathogens like Legionella, aging infrastructure, and evolving industry regulations, ensuring safe, sustainable drinking water is crucial. Our offerings include NSF-certified disinfectants, scale and corrosion inhibitors, and ultraviolet light solutions, ensuring your potable water systems operate safely and efficiently. Most importantly, we provide expert insight into the right chemicals for water that you can utilize in mobile scenarios.

NSF Certification: All our potable water treatment chemicals and solutions meet stringent NSF standards, ensuring safety and compliance.

Comprehensive Solutions: From chlorine dioxide generators to ultraviolet light systems, we offer a wide array of solutions to meet your specific needs.

Expert Consultation: Our team provides expert consultation to help you choose the best treatment options for your facility, working closely with your Water Management Program (WMP) team.

- Chlorine: Effective for routine disinfection.

- Chloramine: Provides longer-lasting disinfection.

- Chlorine Dioxide: Powerful against a wide range of pathogens.

- Ultraviolet Light: Non-chemical disinfection method.

NSF Scale & Corrosion Inhibitors:

- Silicate-Based: Prevents scale and corrosion in potable water systems.

- Phosphate-Based: Provides robust protection against scale and corrosion.

Chlorine Dioxide Solutions and Generators: Offering both the chemical and the equipment needed for effective disinfection.

Chlorine Generators: Reliable generation of chlorine for water disinfection.

NSF Sodium Hypochlorite: Safe and effective chlorine solution for potable water.

Monochloramine Generators: Provides consistent and reliable chloramine for extended disinfection.

Ultraviolet Light Systems: Installation and maintenance of UV light systems for non-chemical disinfection.

Monitoring and Reporting: Continuous monitoring and detailed reporting to ensure optimal performance and regulatory compliance.

Expert Consultation: Tailored advice and support for your potable water treatment needs.

Why Choose Apex

Energy Efficiency

Our water treatment chemicals are tailored to improve energy efficiency for your equipment, keeping costs low and results high.

Ensure Compliance

We ensure that your water solutions align with all regulatory compliance standards, protecting your organization from incurring unwanted costs.

Streamlined Sustainability

Our services strive to reduce environmental impact and create greener, more profitable facilities for clients across a range of industries.

Safety-Focused Services

We utilize touchless deliveries, advanced storage with leak detection, and round-the-clock emergency support, ensuring top-notch safety.