Water Safety

Custom Water Safety at Scale and Value

Why Choose Apex for Your Water Safety Needs

Certifications & Accreditations

Our highly certified and accredited team ensures professional service and quality work in waterborne pathogen testing, Legionella risk management, and advisory services.

Regulatory Compliance

Keeping you compliant is one of our primary concerns, and we ensure that our work meets all local, state, and federal safety standards.

Simplified Reporting

We can reduce your reporting overhead by streamlining your water safety systems to centralize your essential information.

Flexible Solutions

Our flexible water safety solutions can meet your needs no matter how complex your water system or how specialized your working demands may be.

Water Safety Solutions

Water Management Programs

Ensure your water’s safety and quality.

Managing your water is critical to your business operations. We survey facilities to identify risks and develop preventive action plans and remediation services as needed. Our water management programs include treatment, cleaning and disinfecting equipment, and submicron filtration, and they comply with CMSQSO-17-30 and ASHRAE Standard 188-2021, along with state and local guidelines. Our CDC ELITE-certified and A2LA-accredited lab also performs Legionella, Pseudomonas aeruginosa, mycobacteria, HPC, coliform, and other microbiological analyses. Our helpful staff can share these results with you to save you time.

Benefits:

- Ensure the safety of patients, visitors, and employees who contact your water.

- Comply with federal, state, and local guidelines for building occupation standards.

- Build capacity in your organization to understand and analyze water safety test results.

- How does my facility create a WMP?

- Does a WMP require Legionella testing?

- How do I know if our existing plan is properly implemented?

- How can Apex help me with the development and implementation of my WMP?

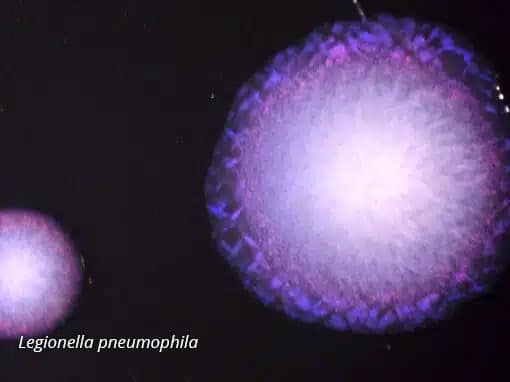

Legionella Testing and Laboratory Analysis

Apex is a reliable Legionella health and safety partner.

Guarding against a Legionella outbreak in your water supply requires constant vigilance and reliable testing. Our Apex A2LA, ELAP, and CDC Elite-Certified facility, along with our ISO 17025 Accredited and ISO 9001 certified chemistry and microbiology labs, can provide timely and accurate results to guard against waterborne pathogen outbreaks. Let us help you reduce your facility’s Legionella risk with our microbiological and chemistry analysis services and comprehensive sampling services. Our team is also ready to consult with yours to help you interpret test results and recommend the best course of action to improve your water quality.

Benefits:

- Partner with a national and state-level accredited lab.

- Meet CMS requirements from ASHRAE 188.

- Receive tailored, cost-effective water testing and analysis solutions.

We provide various Legionella detection options to give our customers the most accurate and timely results.

- Standard - 7–10 Days - Culture

- Rapid - 1-2 Days - QPCR

Secondary Disinfection

Protect your potable water with comprehensive secondary disinfection solutions.

Apex offers a full range of treatments for potable water, helping to mitigate the risk from waterborne pathogens such as Legionella. As concerns about aging infrastructure and evolving regulations grow, we provide a variety of disinfection options, including chlorine dioxide, chlorine, and chloramine. Additionally, our NSF-certified scale and corrosion inhibitors help maintain water quality by preventing infrastructure degradation. With so many disinfectants and treatment methods available, our team will work closely with you to identify the right solution for your facility's specific needs.

Benefits:

- Ensure safe, compliant potable water with effective pathogen control.

- Tailored disinfection solutions to meet regulatory standards.

- Protect your infrastructure with NSF-certified scale and corrosion inhibitors.

- Benefit from expert consultation to select the most suitable disinfection method for your facility.

- Chlorine Dioxide

- Chlorine

- Chloramine

- Ultraviolet Light

NSF Scale & Corrosion Inhibitors:

- Silicate-based

- Phosphate-based

Treatment Systems:

- Chlorine Dioxide Generators

- Chlorine Generators

- Monochloramine Generators

- NSF Sodium Hypochlorite (Chlorine)

- Ultraviolet Light Systems

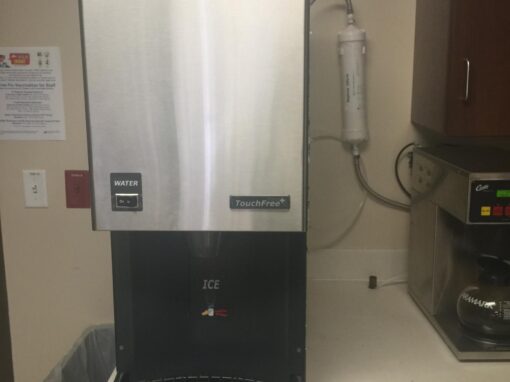

Point-of-Use Filtration

Ensure immediate protection with high-performance infection control filters.

Apex offers Nephros, AquaMedix and Aquatools infection control water filters, designed for healthcare, hospitality, and institutional settings. These filters purify water to meet safety standards, making it suitable for drinking, surgical handwashing, and medical equipment cleaning. With point-of-use filtration and in-line systems, we provide an effective barrier against bacteria, viruses, and endotoxins. Ideal for proactive water management and immediate response to bacteria-based water events, including Legionella outbreaks, our solutions offer quick installation and long-lasting performance.

Benefits:

- 0.2 down to 0.005-micron pore sizes available for tailored protection.

- FDA Class II filters ensure the highest standards of water purification.

- Quick and easy installation to support immediate water safety needs.

- Extended filter life minimizes maintenance and enhances operational efficiency.

- ≤ 0.2 micron pore size

- Quick and easy installation

- Effective barrier for bacteria

- Ideal for immediate response to bacteria-based water events and outbreaks

- Application at sinks and showers

- 90-day filter life

In-Line Filtration Features:

- 0.005 micron pore size for DSU & SSU models

- Purifies water suitable for wound cleansing

- Suitable for ligature-free environments

- Effective barrier for bacteria, viruses, and endotoxins

- Ideal for proactive water management

- No changeouts necessary during incidents of biological contamination

- Application at sinks, showers, manufacturing/healthcare equipment, and ice machines

- 90- to 180-day filter life

FDA Class II Filter Models:

- S100 Sink Spout

- S100 Sink Spray

- S100 Shower Handheld

- SSU-H Single Stage

- DSU-H Dual Stage

- CleanSpray Faucet

- Wallshower

- Baclyser Inline

- Filt’Ray Faucet & Shower

Sterile Processing Critical Water

Maintain strict water quality standards with AAMI ST108 compliance.

Apex provides water treatment solutions designed to meet the stringent requirements of AAMI ST108 for the processing of medical devices. This standard defines multiple levels of water quality and steam purity, ensuring that your water treatment system is capable of producing water that meets these exacting standards. From reverse osmosis (RO) units to bacteria filters, we help design, install, and maintain continuous loop systems that ensure the safety and performance of your sterile processing operations. Our solutions are tailored to minimize risk and ensure compliance with AAMI ST108.

Benefits:

- Meet AAMI ST108 standards for critical water quality in medical device reprocessing.

- Continuous loop system designs with monitoring and alarms to ensure water quality.

- Monthly disinfection options, including ozone, chlorine, peracetic acid, and hydrogen peroxide, to keep systems within compliance limits.

- Comprehensive support for testing, bacteria, endotoxin and ionic compounds specified in ST108

Cooling Tower Cleaning & Disinfection

Comprehensive cleaning and disinfection to protect your cooling towers.

Apex provides a full-service program for cooling tower cleaning, disinfection, and inspection, following industry best practices and OSHA recommendations. Cooling towers should be cleaned and disinfected at least twice a year to prevent harmful microorganisms like Legionella from developing. Our process includes a thorough pre-disinfection, physical cleaning, post-disinfection, and detailed documentation. By partnering with Apex, you can ensure the safety of your guests, staff, and facility while maintaining compliance with all regulations.

Benefits:

- Minimize Legionella risk with semi-annual cleaning and disinfection.

- Boost performance through professional cleaning and debris removal.

- Stay compliant with OSHA and industry regulations.

- Get detailed service reports with photos and a certificate of completion.

Our Process

Assemble a Cross-Departmental Team

We form a cross-departmental team to oversee your water safety plan.

Map Out Water System Flow

Our team diagrams your building’s water systems to create a detailed process flow.

Identify Critical Control Points

As we assess your water system, we’ll identify critical control points.

Implement Control Measures

We establish and implement control measures for these critical points.

Develop a Monitoring and Action Plan

Our team will develop a monitoring schedule with corrective actions to ensure ongoing safety.

Verification & Review

The WMP team meets to verify program implementation, effectiveness of hazard control, and review test results.

Comprehensive Documentation

You’ll receive comprehensive documentation to ensure compliance and for future reference.

Water Safety Updates & News

Case Studies

An absolute phenomenal team to work with.

“I have the utmost respect for the team’s expertise and professionalism. A great group to work with and always appreciate the support and guidance. Thank you for all that they do for our organization.”

I can’t say enough good things about Team Apex.

“They are very important to the operations of our facilities. Darci and Will are also forward looking and provide our facilities strategic and innovative methods of our water management program.”

Apex and everyone there are the best.

“Worked with them 20+ years now and never had a single issue with them.”