Authors

Mike Bertrang – VP of Sales

In an era of increasing water scarcity and environmental regulations, closed-loop water systems are becoming increasingly important in industries worldwide. With proper design, operation, and treatment, closed systems can be a sustainable solution to water management in industrial settings.

What are Closed-Loop Systems?

A closed industrial water system is a water distribution system in which water is circulated through pipes, equipment, and cooling or heating units, but it is not exposed to the external environment. Water in these systems is recirculated, typically undergoing filtration or treatment to maintain its quality. Closed systems can be found in many industries, including power plants, chemical plants, HVAC systems, and manufacturing processes.

What are the Components of a Closed-Loop System?

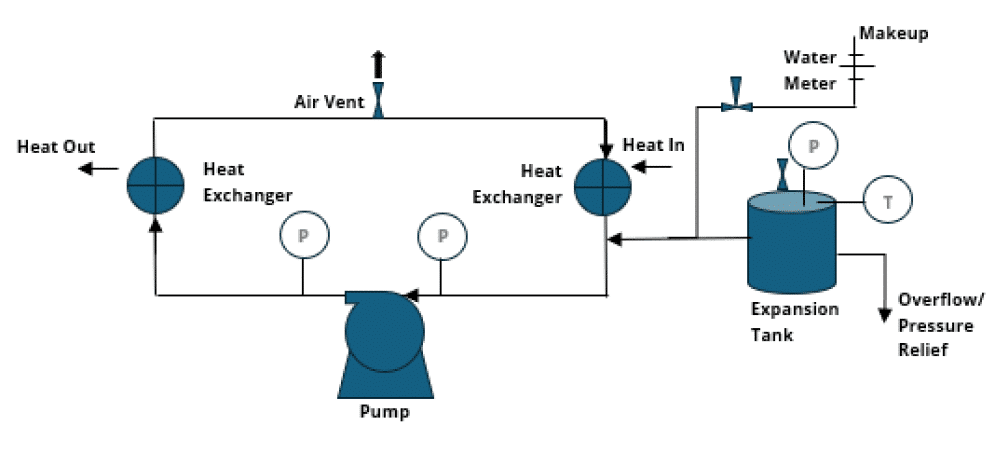

- Pumps: These circulate water through the system, ensuring consistent flow and pressure.

- Heat Exchangers: Heat exchangers are used to transfer heat between water and another medium (such as air or secondary fluid) to maintain desired temperatures in industrial processes.

- Expansion Tanks: These compensate for changes in water volume as the temperature fluctuates, preventing system pressure from rising too high.

- Piping: A network of pipes transports water to various parts of the system. Materials used for pipes must be durable and resistant to corrosion or scaling.

- Valves: Valves control the flow of water throughout the system and allow for maintenance or adjustments to the water flow.

- Filtration and Treatment Systems: These ensure the water remains clean and free from contaminants, scaling agents, and microbes. Common treatments include chemical dosing and filtration units.

- Cooling Towers or Chillers: In systems designed for cooling, cooling towers or chillers are used to expel heat from the circulating water.

What are the Different Types of Closed Systems?

- Closed-loop Cooling Systems: Used for cooling industrial equipment such as engines, turbines, or electronic components. Water circulates through a heat exchanger and then returns to the system after the heat is dissipated.

- Closed-loop Heating Systems: These systems use water as a heat transfer medium in boilers, radiators, or industrial heating processes.

- Chilled Water Systems: Water is chilled to low temperatures and circulated through the system to absorb and remove heat from equipment or spaces.

What are the Advantages of Closed Systems?

Closed-loop systems provide significant advantages including water conservation, reduced contamination, improved control, energy efficiency, and extended equipment life.

- Water Conservation: Since water is continuously recirculated, there is less need for a constant water supply from external sources, making the system more environmentally sustainable.

- Reduced Contamination Risks: The sealed nature of closed-loop systems prevents external contamination from affecting the water, reducing the risk of bacteria, algae growth, and other pollutants.

- Improved Control: Temperature, pressure, and flow rate can be controlled more precisely in closed systems, leading to better efficiency and performance.

- Energy Efficiency: Closed systems are often more energy-efficient because they maintain thermal balance within the system, reducing the need for frequent heating or cooling.

- Extended Equipment Life: By reducing the potential for contaminants or corrosive agents, closed-loop systems can extend the lifespan of industrial equipment that depends on water circulation.

What are the Challenges of Closed Systems?

Although closed-loop systems offer several advantages, they require careful management to maintain efficiency. Some of the key

challenges include:

- Corrosion and Scaling: Over time, closed systems can develop scale or rust, which can hinder water flow, reduce heat transfer, and damage equipment. Routine monitoring and chemical treatment are essential to mitigate these risks.

- Leaks: Even though the system is designed to be sealed, leaks can occur over time due to wear, pressure changes, or poor maintenance. Identifying and repairing leaks promptly is essential to avoid water loss and pressure fluctuations.

- Water Treatment: To maintain water quality, chemicals may need to be added periodically to control pH, prevent algae or microbial growth, and combat corrosion or scaling.

- System Monitoring: Regular monitoring is required to ensure that the system is running at optimal efficiency. Sensors, gauges, and control systems can track temperature, pressure, and flow rate to help identify potential issues before they become significant problems.

What Chemistry do we Use in Closed Systems?

Water treatment is a crucial part of maintaining a closed industrial water system. Without adequate treatment, contaminants like calcium, magnesium, and other minerals can cause scaling, while microorganisms can cause biofouling. Understanding the chemistry used in closed systems will help you make an informed decision on what Apex products to choose for your application.

Corrosion Inhibitors

Nitrites: Only effective with steel. Will react with aluminum aggressively.

Molybdates: Effective steel inhibitor at high levels. Can be combined with silica and azoles for aluminum inhibition.

Borates: pH buffer with steel corrosion inhibition properties

Azoles: Yellow metal corrosion inhibitor (brass/copper)

Silicates: Steel filming inhibitor

Nitrates: Aluminum corrosion inhibitor

Dispersants

Acrylic Acid (AA): Excellent carbonate dispersant.

AMPS: Phosphate dispersant

Sulfonic Acid (SA): Iron Oxide dispersant.

Scale and Corrosion Inhibitors

HEDP: Scale-inhibiting phosphonate with some steel corrosion inhibiting properties.

HPAA: Scale-inhibiting phosphonate. It has much better steel corrosion inhibiting properties than HEDP. It also has some dispersant properties.

POCA: Scale-inhibiting polymer designed for sulfate and silica scales. Contains some corrosion-inhibiting properties.

Maleic Acid: Crystal modifier and scale inhibitor.

Chelating Agents

Citric Acid: Effective chelant on iron-based deposits

Gluconic Acid: Chelating agent on iron deposits. Can also act as a cathodic steel inhibitor and a dispersant.