Why must we control biological growth?

Biological growth in water systems is a serious public health concern and can be attributed to major illnesses, such as Legionnaires Disease, a severe form of pneumonia from the Legionella bacteria. Without the control of biological growth in cooling systems, outbreaks of these diseases are possible. Additionally, biological growth can be directly detrimental to cooling systems, causing:

- Fouling/scale

- Corrosion

- Loss of heat exchange capacity

- Clogging

- Equipment failure

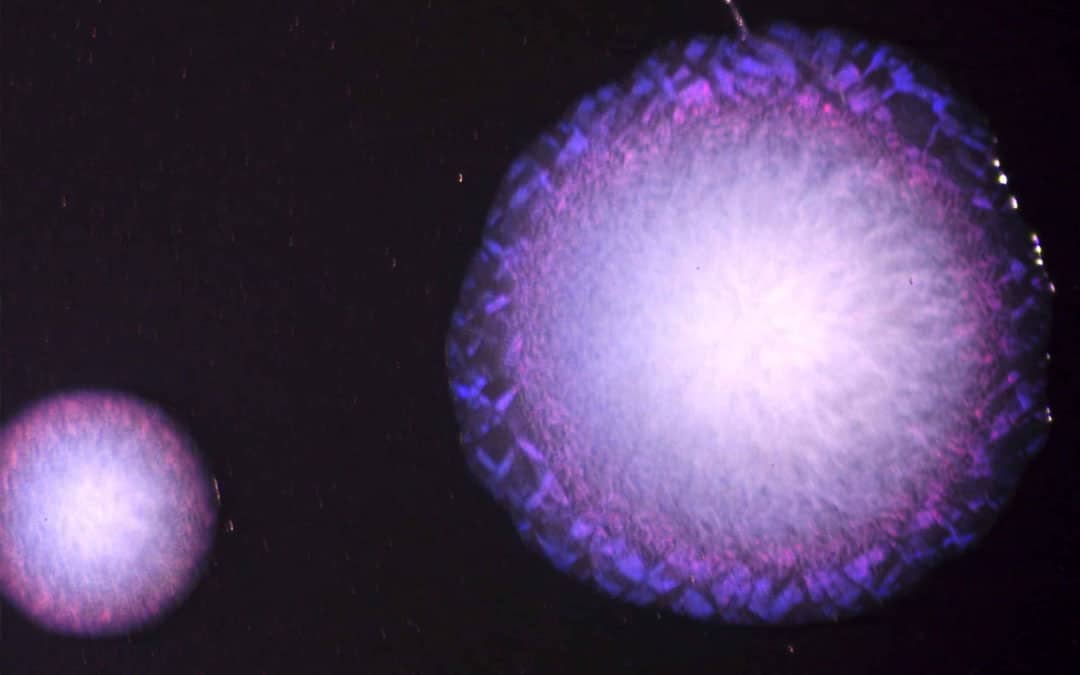

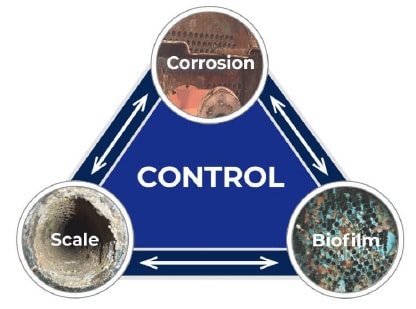

Figure 1. Controlling biofilm in cooling towers can

protect against further corrosion and scale.

What are the different types of biological growth?

The three types of biological growth in cooling water systems are algae, fungi, and bacteria.

- The easiest method to control algae is to cover the deck of a cooling tower. This will remove nearly all possible sunlight required for growth.

Fungi are most found in wooden cooling towers, causing both surface and internal decay. Fungi use wood as their primary food source, “chewing” away at the wood, leading to soft and darkened spots. Eventually, the wood section will decay enough to cause failure. Fungi are found on metals and plastics in cooling towers, as well. This can often happen when other biofilm is already present.

- Fungicidal products are the required method to control fungi growth. When cooling towers undergo cleaning, the necessary fungicidal product should be sprayed on all exposed sections.

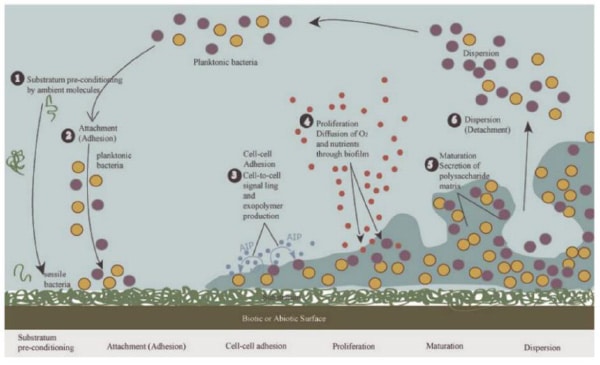

Figure 2. The stages of biofilm formation.

How do we control biological growth?

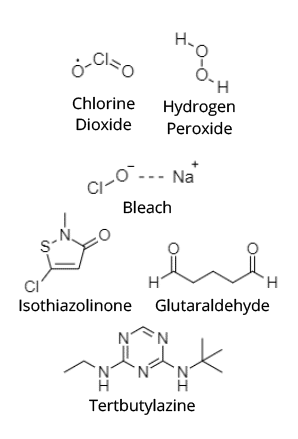

Biocides are chemical formulations designed to control biological growth. The two types of biocides used to treat cooling water systems are oxidizing and non-oxidizing biocides.

Oxidizing biocides can control microbiological growth through the electrochemical process of oxidation. Oxidizing biocides, such as chlorine, bromine, and hydrogen peroxide, are electrophilic (want more electrons) and steal electrons from bacteria, leading to the stoppage of the bacteria growth cycle. These biocides are generally sufficient for planktonic bacteria (free-floating). Oxidizing biocides are most widely used because they are cheap, fast-acting, and effective at low concentrations. A disadvantage of oxidizing biocides is their ability to cause corrosion. It is recommended to pair oxidizing biocides with corrosion inhibitors.

Non-oxidizing biocides exterminate bacteria through various processes, including cell wall rupturing, inhibition of reproduction, and the breakdown of bacterial enzymes. Some common non-oxidizing biocides include tertbutylazine, isothiazoline, and glutaraldehyde. These biocides are required when sessile bacteria (surface-attached) form biofilms. Unlike oxidizing biocides, non-oxidizers will not cause corrosion. Unfortunately, their specific mode of action against microbiology can lead to resistance.

How do we effectively use biocides?

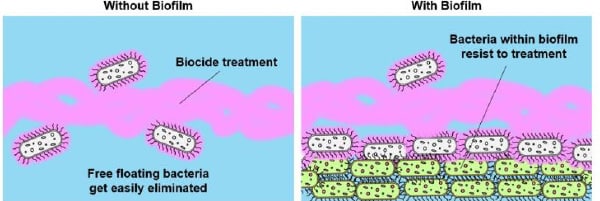

There are usually two ways to feed biocides to cooling water systems. The first approach is by using two biocides that complement each other. This is often accomplished by alternating between non-oxidizing biocides and oxidizing biocides. The non-oxidizing biocide will disperse the upper layers of the biological growth, allowing the oxidizing biocide to more effectively attack deeper layers of the growth. Without this help, the biofilm will resist the treatment, as shown below. As the oxidizer attacks these layers, the non-oxidizer can more effectively disperse the organic matter. As such, the dual action of both products will improve their results. The oxidizing biocide is fed continuously every day while the non-oxidizer is fed every three to four days. If a system has little to no microbiological growth, then an oxidizing biocide running continuously is highly recommended.

What biocide should I use for my cooling tower?

Understanding and recognizing the pH and biological growth in your system can aid in your selection of treatments. Biocides are limited by their chemical composition to being effective only at certain pH ranges or on specific groups of biological growth. Once the identity of the biology is determined, the correct biocide can be chosen for your applications.