Installing a Chemical Feed System is more complicated than most think! There are many overlooked logistics that can turn your Chem Feed System into a huge pain.

These are 8 of the top mistakes we see in the industry:

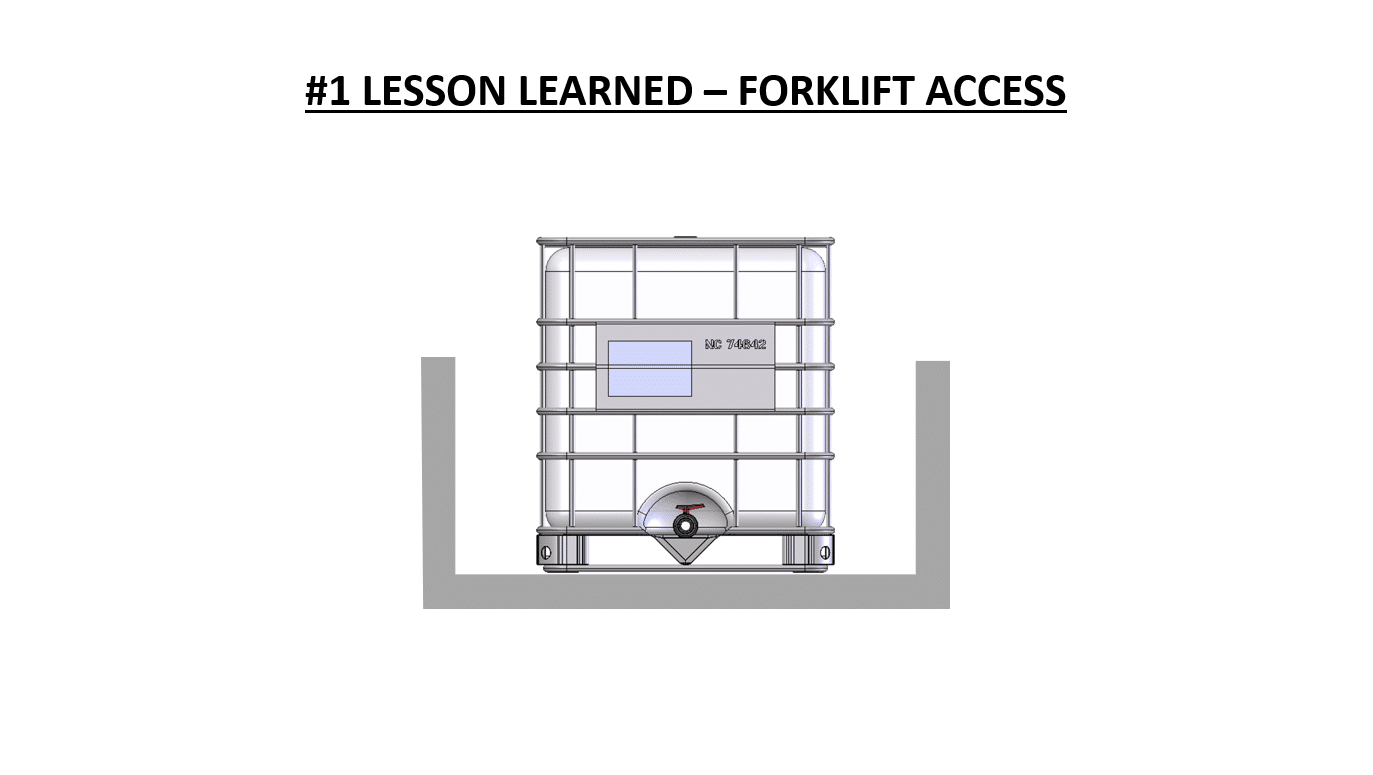

1. Forklift Access

- Wall height is too tall

- Not accessible with a forklift

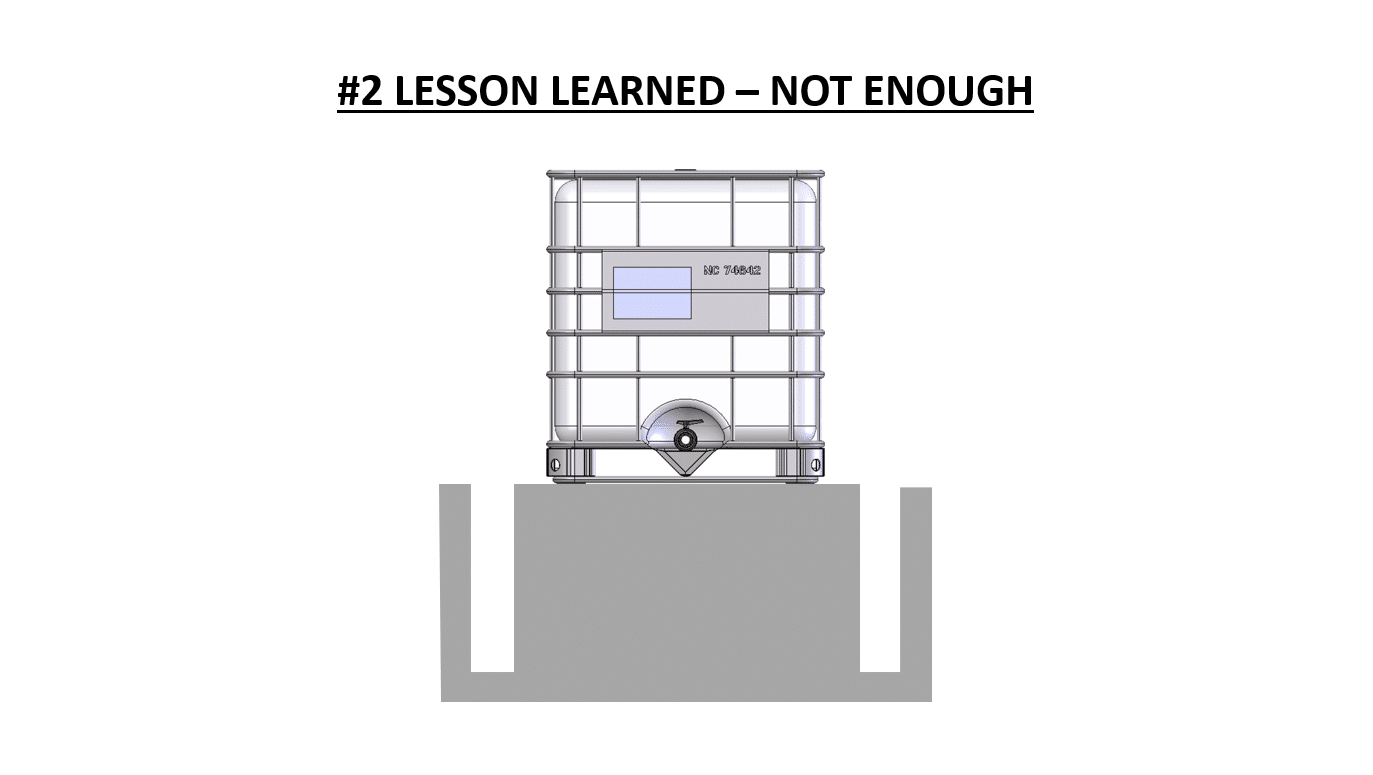

2. Small Containment Volume

- Not enough drainage

- Displacement reduces the volume to <110%

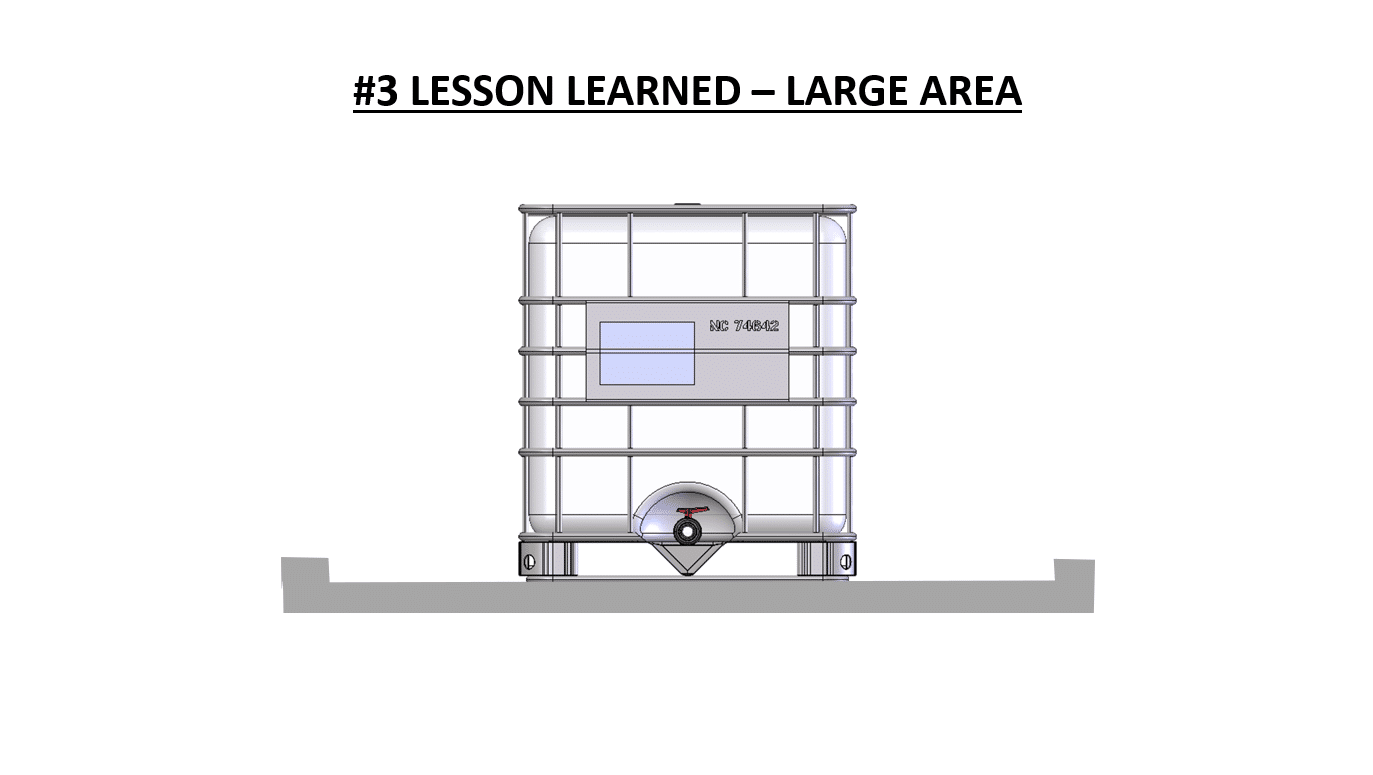

3. Occupies a Large Area

- A large footprint takes up a lot of real estate

- The tote is less accessible

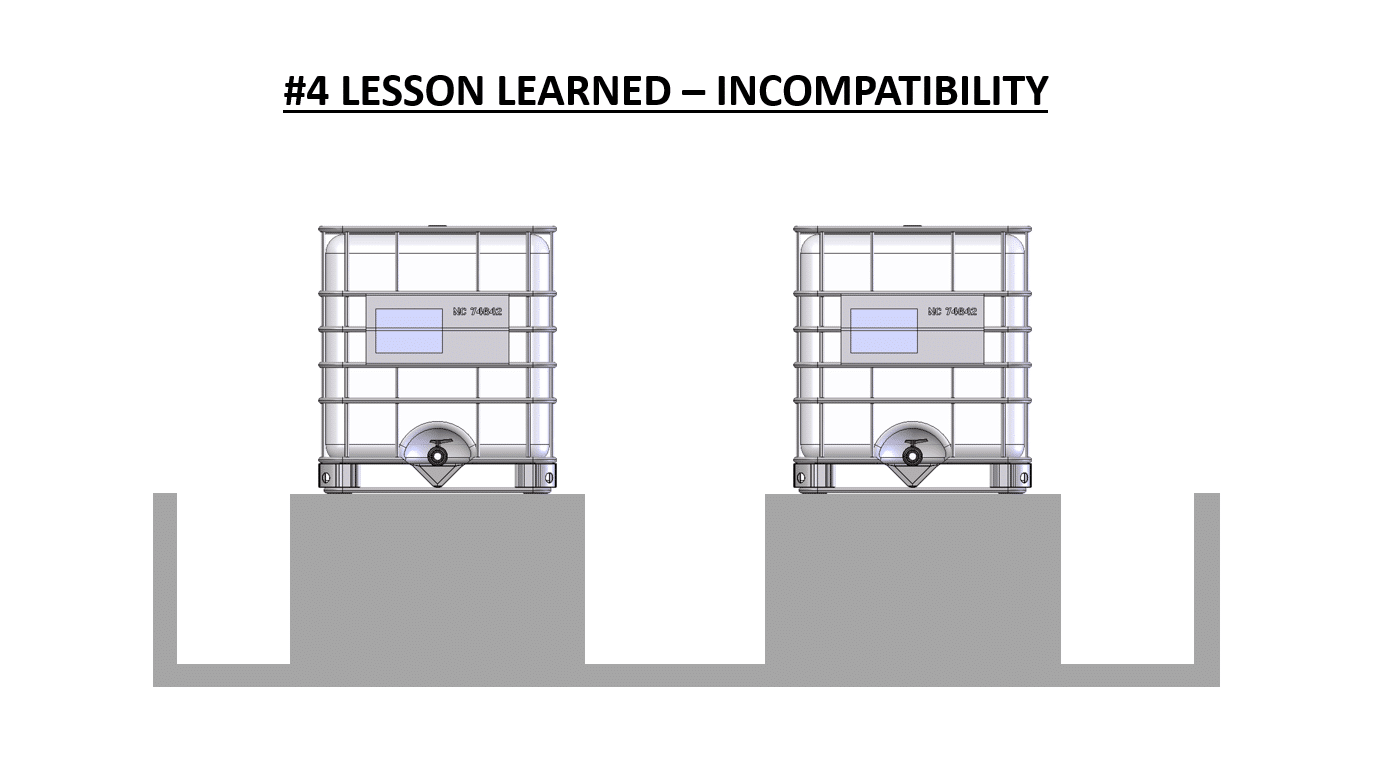

4. Incompatibility

- 2 or more chemicals sharing the same containment bin

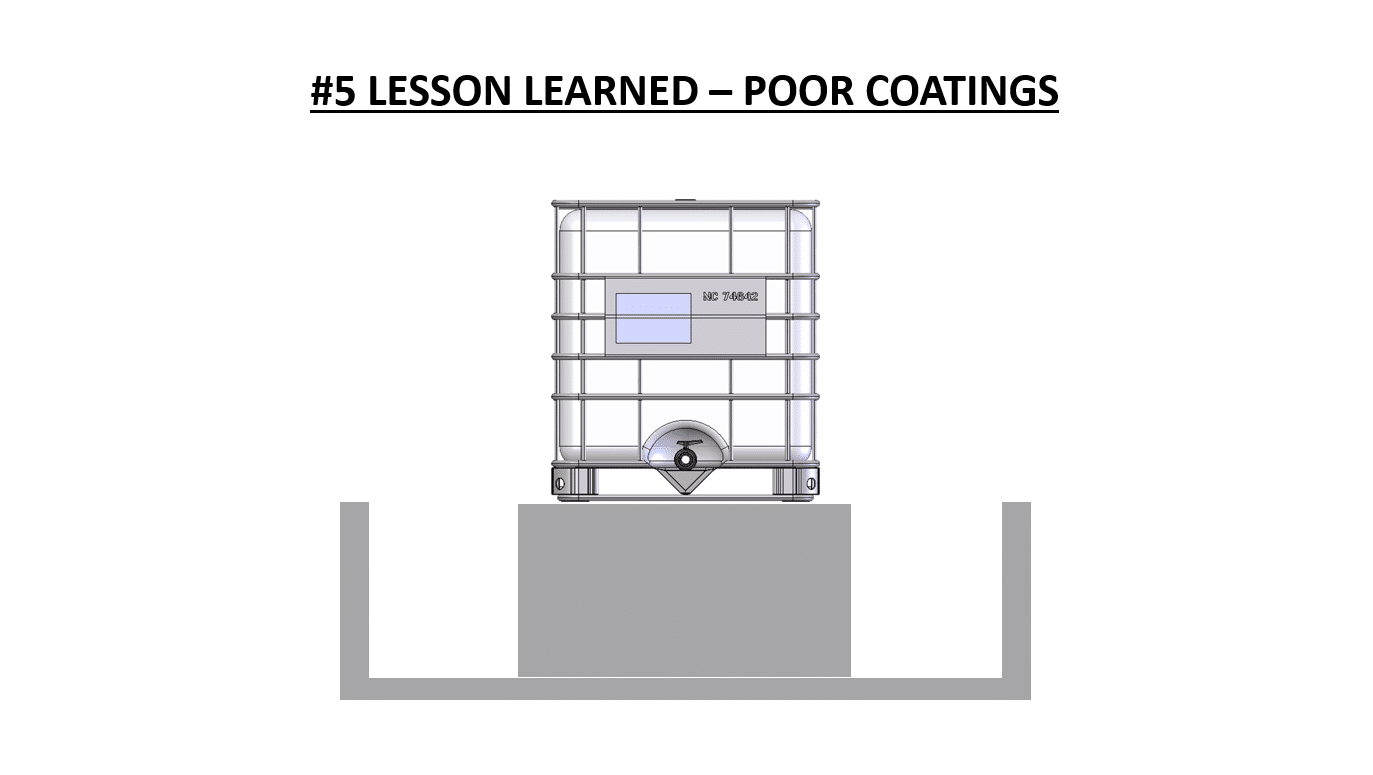

5. Poor Coatings

- Incompatible coatings get destroyed on the first leak

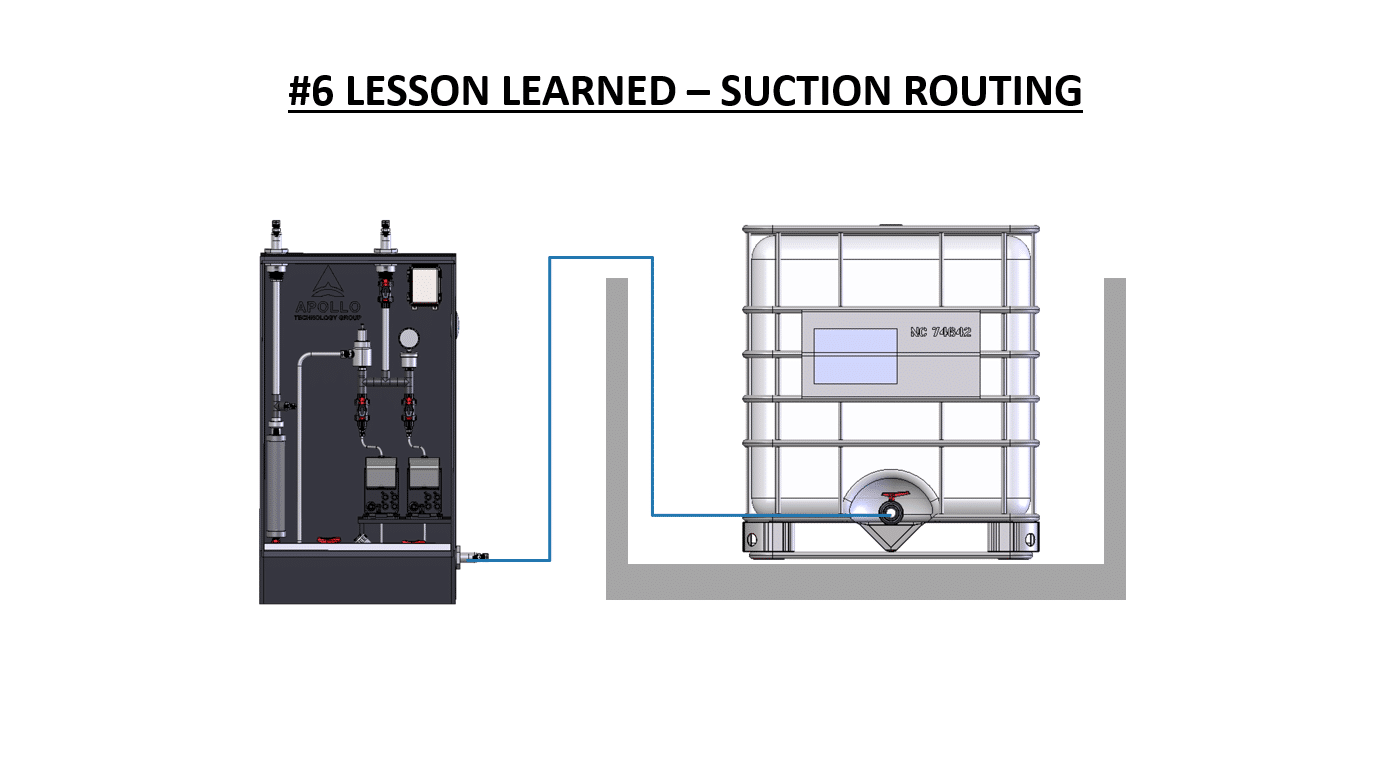

6. Suction Routing

- Tubing up/down

- This set up leads to loss of prime of pumps

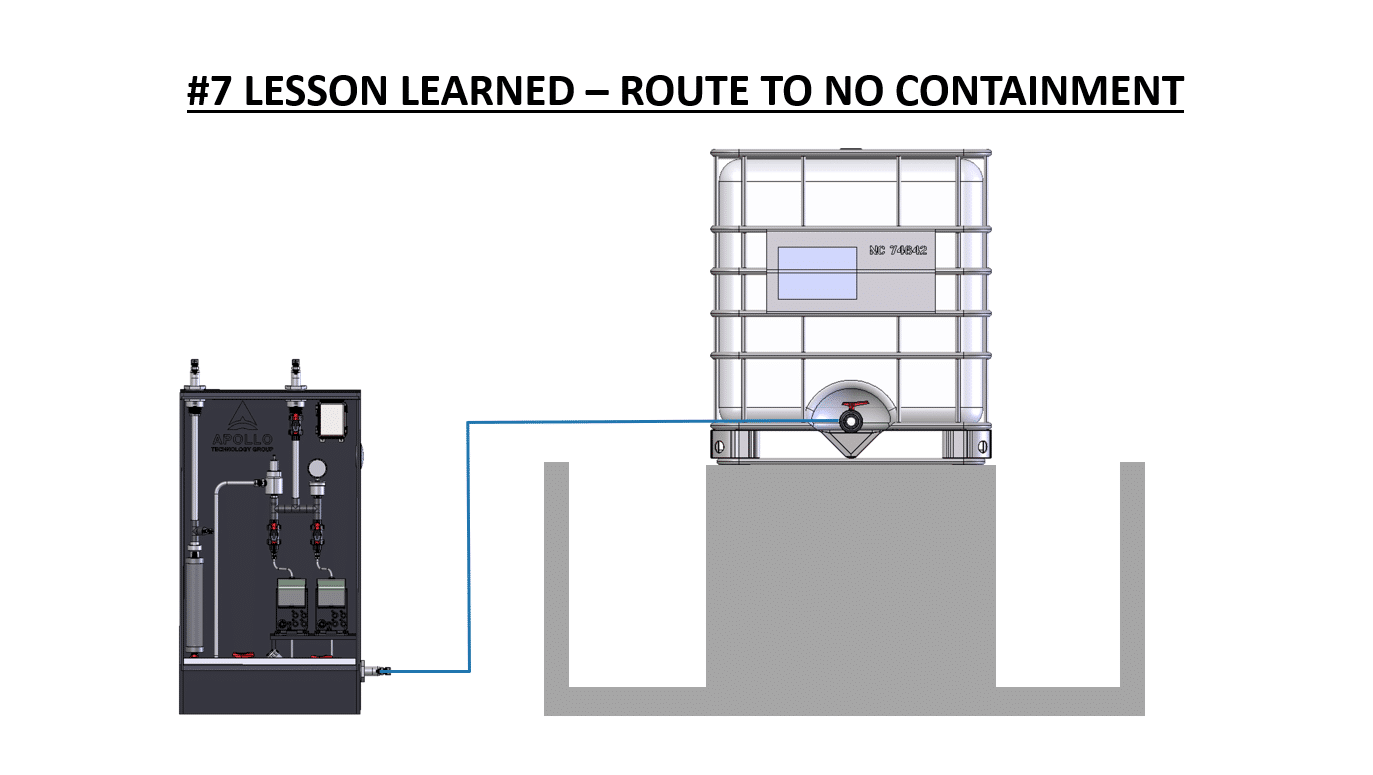

7. Route to No Containment

- Risk of leak escaping containment

- A leak may run down the tubing and drain outside of containment

- A leak may also develop on the chem feed skid and tote contents drain

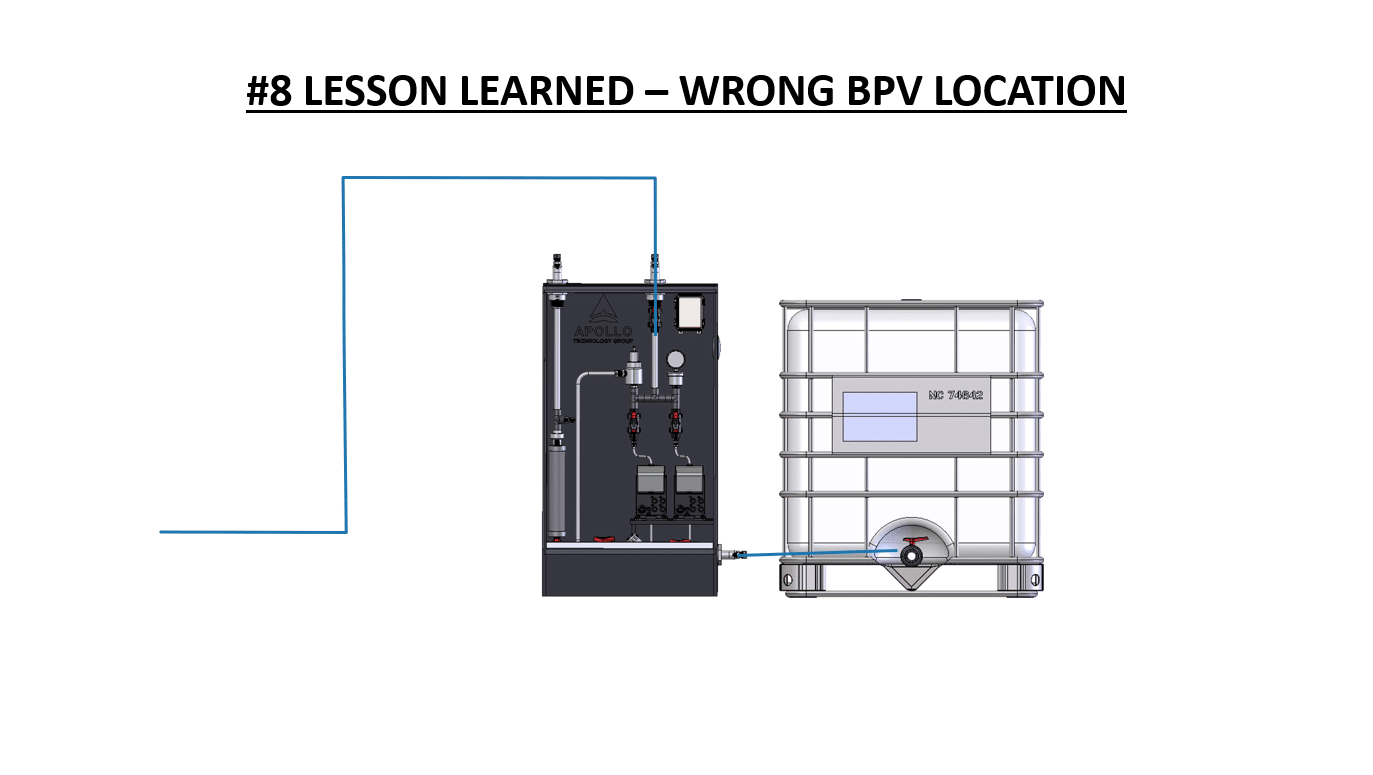

8. Wrong BVP Location

- BVPs on skids vs. injection locationl

- BVPs would be installed at the injection point instead of located on the skidl

- This provides better chemistry control

Our SafeFeed systems address common issues and pain points that occur with industry-standard CDUs.

When installing a Chemical Feed System most of the logistics are overlooked because it seems like a simple process. Learn more about our SafeFeed System; which is our solution to these problems!