Bruce Ketrick, Sr CWT

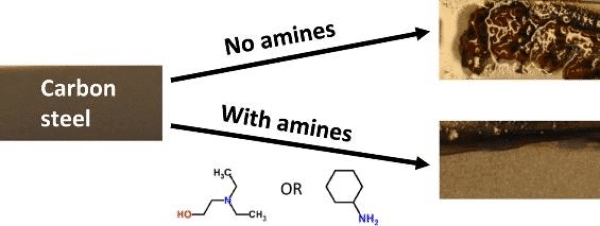

The boiler condensate return line system is the system where the selection of a program can easily result in failure. When failure occurs in the return line system, it carries over into the feed water and the boiler water system, as corrosion byproducts result in cascading failures in these related systems, as well. Amines are commonly used to treat the boiler condensate return line. Amines fall into two major categories for treatment: Neutralizing and Filming.

What are Neutralizing Amines?

Neutralizing amines are used to control carbonic acid corrosion in the boiler condensate return line. As these alkaline amines are used, you neutralize any carbonic acid that is formed. Without doing so, the condensate return piping will be destroyed and iron will be introduced again into the feed water system. Neutralizing amines are volatile and completely soluble in the boiler water. Neutralizing amines are categorized based on the distance they can travel “down pipe”.

How do I Determine what Neutralizing Amines to Use?

Once it is determined how many runs there are in the system, the length of runs will need to be determined. This will influence if one or more amines will be needed in this system. It is common to use a blended amine product for multi-run systems.

Cyclohexylamine will stay in the condensate system over long runs and in low pressure situations. It volatilizes in the boiler and carries with the steam. As such, it should not be added to a deaerator or feed water tank. In these vessels, water is heated to drive off oxygen.Cyclohexylamine becomes volatile at 205°F and, therefore, injecting it into the deaerator will cause it to be released with the oxygen and drive up the feed rate requirements.

Diethylaminoethanol (DEAE) is a good medium range amine but does not have the ability to pass over long runs and through pressure-reducing stations below 15 psi. DEAE as a 25% or 50% solution is the most widely used neutralizing amine. In many accounts, DEAE is being fed where there is one long run and some low-pressure reducing stations. In these cases, the largest part of the system is protected, but a small section is not. As such, cyclohexylamine needs to be blended with DEAE. The new combination product now protects both the long and medium runs of the system. Similar to cyclohexylamine, DEAE should not be added to a deaerator or feed water tank.

Morpholine is used for short runs and will have to be blended with one or both of the other neutralizing amines if the system is more than a short run. Morpholine is used where turbines are contacted with sufficient steam pressure. The volatilization temperature of morpholine is 264°F, so you must have over 40 psi for this neutralizing amine to remain in the steam. Where the steam passes through pressure-reducing stations, morpholine will drop out due to the lower steam temperature and may concentrate in this localized area. It can then carry back with the condensate at a higher pH than is normally seen in the system. This localized high pH will not cause harm to iron-based pipe but can be seen as a blue sludge deposit where it contacts copper-bearing heat exchangers. Morpholine is also highly aggressive on the site glass gaskets and seats. This can result in steam leaks that cause site glass silica loss and site glass failures. This is why morpholine should only be used where short run or high-pressure applications require its use.

Diethylhydroxylamine (DEHA) is both a volatile amine and a passivating agent for control of oxygen in the boiler system. It can be added to the deaerator to protect the feed water system from oxygen pitting. Once added, DEHA will carry into the boiler for oxygen protection and then volatilize with the steam and carry through the steam and condensate return line. Since DEHA is an extremely strong reducing agent, it has the ability to convert iron oxide corrosion by products into passive magnetite throughout the entire boiler system. It is important to note that DEHA is not FDA approved and is not recommended with sodium sulfite programs, as both are reducing agents and tend to compete. Similar to morpholine, DEHA is non-azeotropic in water, meaning it does not have a constant boiling point and can be separated from water through distillation, unlike cyclohexylamine or DEAE. The flash point of DEHA is approximately 113oF but that is specific to the raw material. It can be concerning to see the low flash points of amines, but, when added to water, those flash points will increase to a temperature suitable for normal operating and handling conditions. For example, cyclohexylamine has a low flash point around 90oF, but its dilution in water will increase the flash point to well above 180oF.

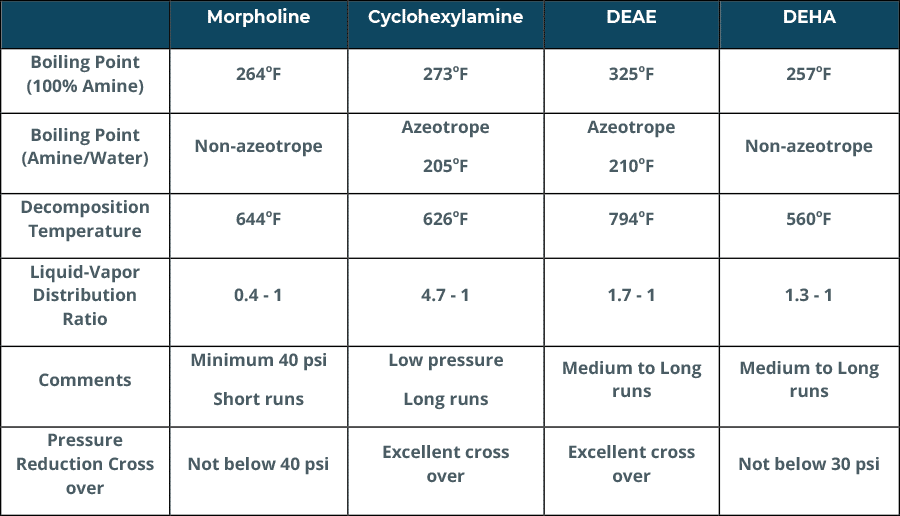

Table 1. Summary of the properties of common neutralizing amines

When do I Use Filming Amines?

Neutralizing amines have no effect on oxygen in boilers while filming amines do. Inevitably, vacuum breakers in a line will pull oxygen in during operation. This will show up as oxygen pitting in lines. This is when a filming amine or an FFA (volatile filming amine) will need to be added to the system, to protect against the oxygen that is being pulled into the lines.

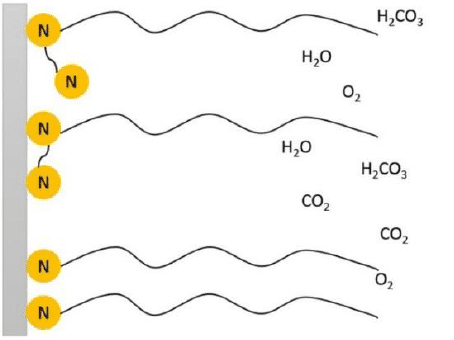

Filming amines are aliphatic hydrocarbon-based materials that protect the condensate return line by laying down a film on the metal surface. This film will protect the metal from corrosion by preventing oxygen from contacting the metal surface. Where steam dryers and pressure reducing stations are part of the system, you are normally limited to the use of neutralizing amines and FFA (volatile filming amines). Paraffinic filming amines, such as the long chain Octadecylamine (ODA), by their nature drop out as a wax coating. Any restriction in flow or pressure acts as a trap for the filming amine and the result is a clogged system. Where this problem exists, the use of neutralizing amines will thin the filming amine build up and slowly remove it from the system. Should oxygen prove to be a problem in this system, the filming amine will have to be added after the dryer or pressure reduction area.

The proper condensate treatment for a dryer or pressure reducing station should be a dilute filming amine solution that has been blended with neutralizing amines, or an FFA so that it will carry down the lines. There is a difference between Octadecylamine filming amines and FFA volatile amines. ODA does not volatilize well and does not travel down the system without the addition of neutralizing amines. Contrary, the FFA is highly volatile and can travel the length of the steam and return line piping, protecting the entire system.

Alternative Condensate Return Lines Treatments

FDA, USDA, and Dairy Plants

If the plant is under USDA or FDA control, then the type of product used, and the amount allowed in the system are established by these agencies. If the account is a dairy plant, the only acceptable amine for the system is aqueous ammonium hydroxide. In this case, consult the plant agency inspector as to what they will allow.

National Organic Program Certified Plants

If the plant is organic certified under the USDA NOP guidelines, then a non-amine-based product will need to be used. Apex’s new organic-approved product is Vapor OC. This material provides effective steam condensate treatment for organic food manufacturers under USDA NOP standards.