Overview

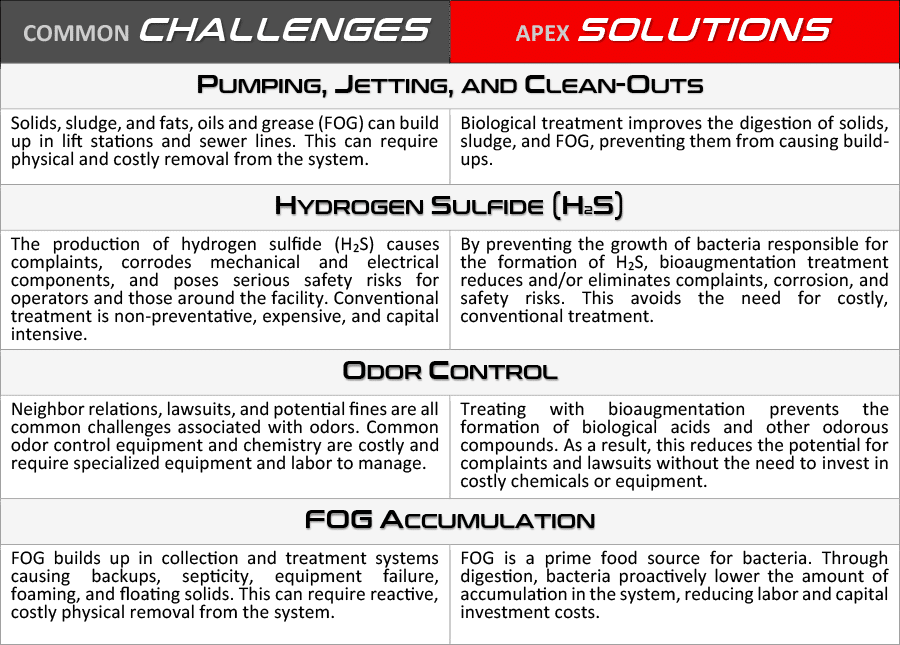

Some of the main challenges faced by lift station operations include odor complaints, the need for costly chemical treatments to control hydrogen sulfide, equipment corrosion and failure, physical removal of built up solids as well as overall safety risks.

Apex’s BioArmor™ Treatment Program is designed to support lift station operators facing these costly challenges by targeting fat, oil and grease (FOG), sludge, odor and hydrogen sulfide (H2S).

Program Approach

While each lift station opportunity is unique, the basis of our BioArmor™ Treatment Program remains the same:

- Apex representatives complete a comprehensive system survey.

- We develop a program to instruct operators on where, when, and how to apply the BioArmor™ products to ensure the treatment is successful.

- Our experts demonstrate and instruct on how to properly measure and document progress before, during, and after treatment.

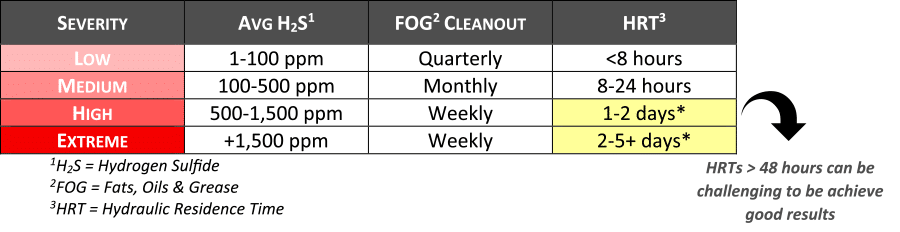

Assess Severity

The table below assigns the severity. The three primary variables are outlined below, and selecting the most extreme of either H2S, FOG cleanout frequency, or the HRT of the forced main will classify the severity of the particular lift station.

Challenges & Solutions

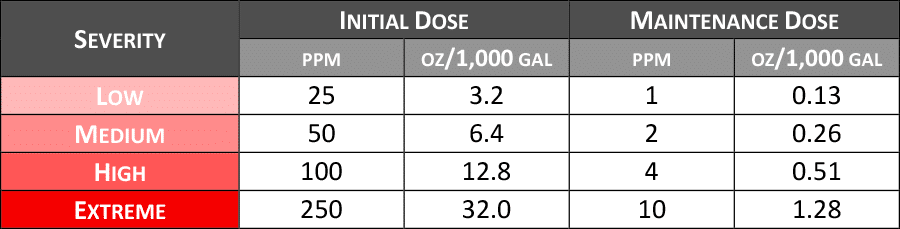

Treatment Approach

BioArmor™ LiqC should be added as far upstream as possible. Based on the severity of the lift station, the following dossages of BioArmor™ LiqC should be added. The initial dose should be maintained for 1 to 2 weeks.